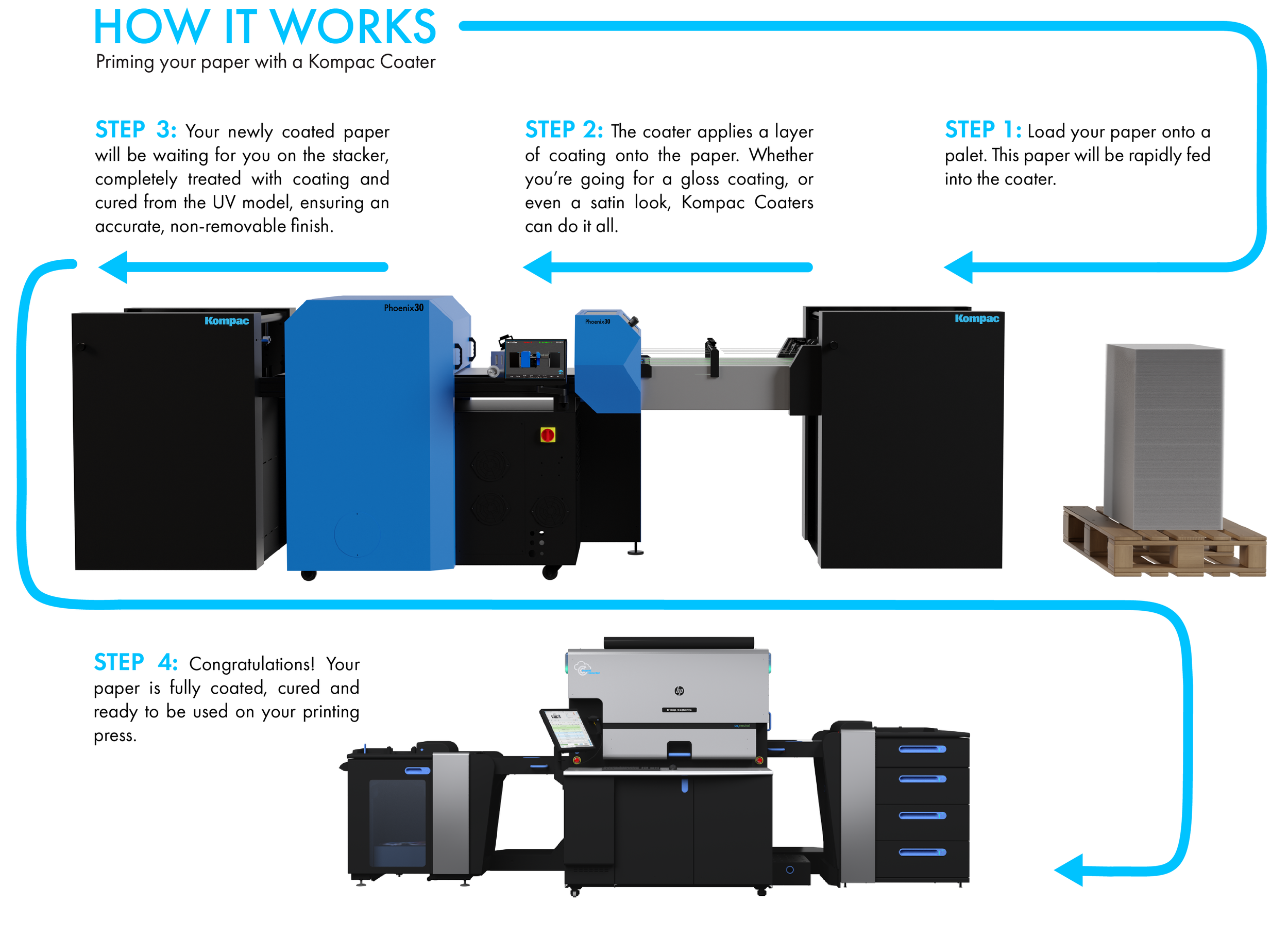

Pictured: Kompac Phoenix 30 S sheet-fed with feeder and stacker.

Paper shortages can be a painful reality for printing companies. The current paper shortage can hit these companies hard, and, in most cases, it is out of the companies’ control. For the duration of the pandemic and even now, the weakening of the global supply chain means that these shortages of resources such as paper aren't going to go away anytime soon. This correlating to the rising price of timber has affected the paper industry harshly. The shortage of paper is creating a large issue right now for those in the paper industry, because acquiring paper with a specialized coating is becoming exceedingly rare, not to mention specific dimensions of paper being outright impossible to acquire. This has led to drastic changes in what size paper can be used for printing in bulk. With the demand for paper being so high now, it’s making more and more sense for paper distributors to look towards alternatives when it comes to making specifically coated paper in house, rather than outsourcing it elsewhere. What if there was a way to have your own paper treated with primer, without having it ever leaving the building?

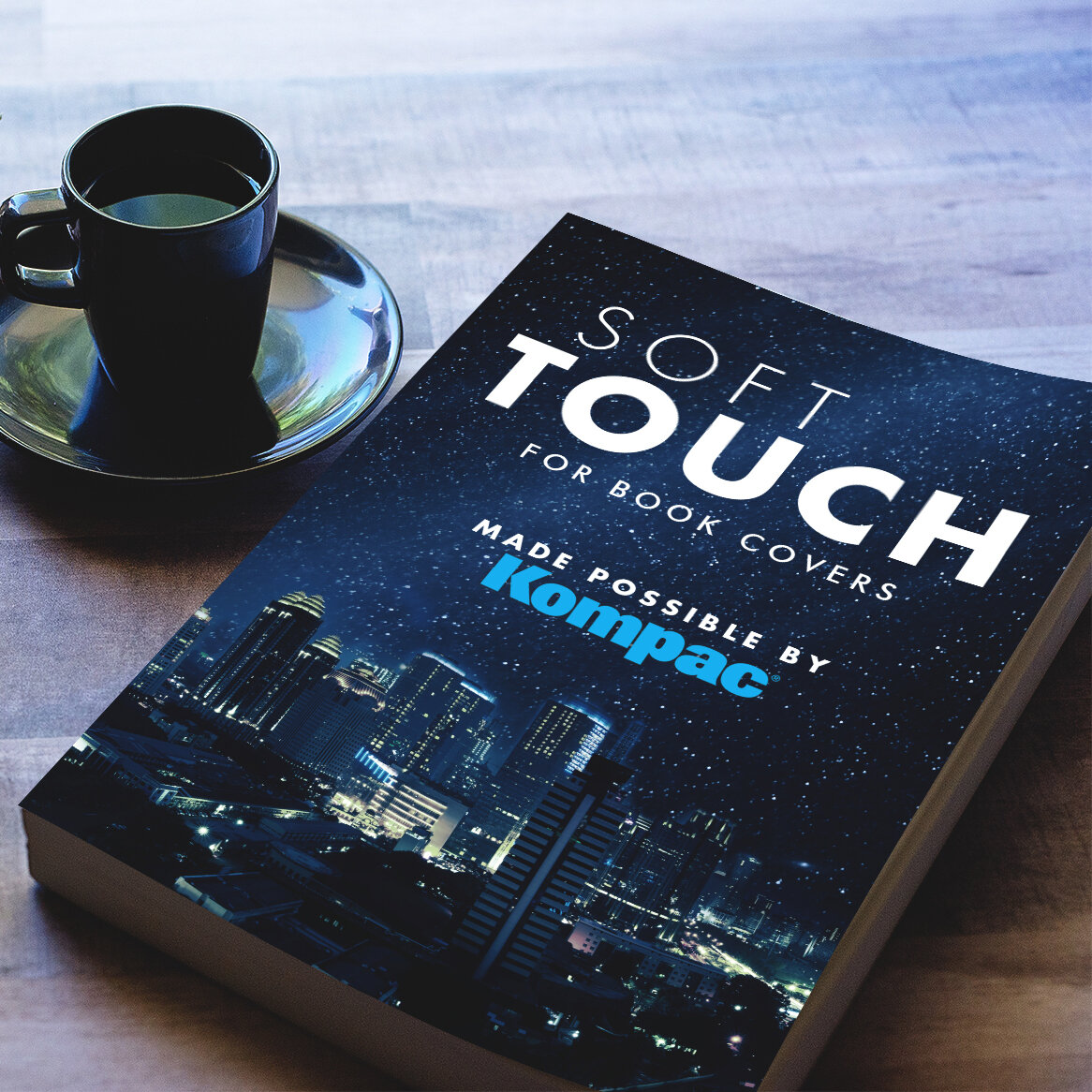

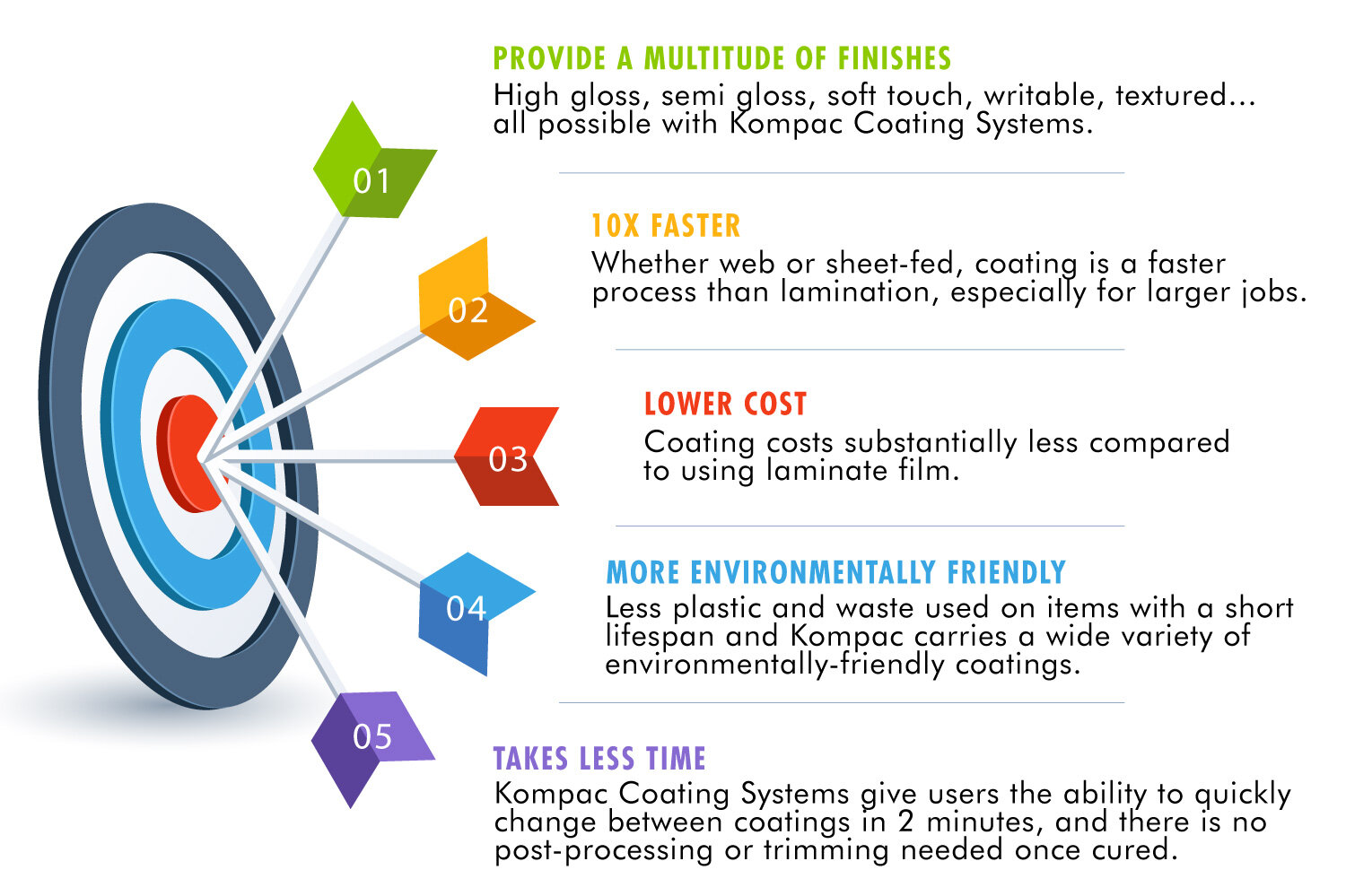

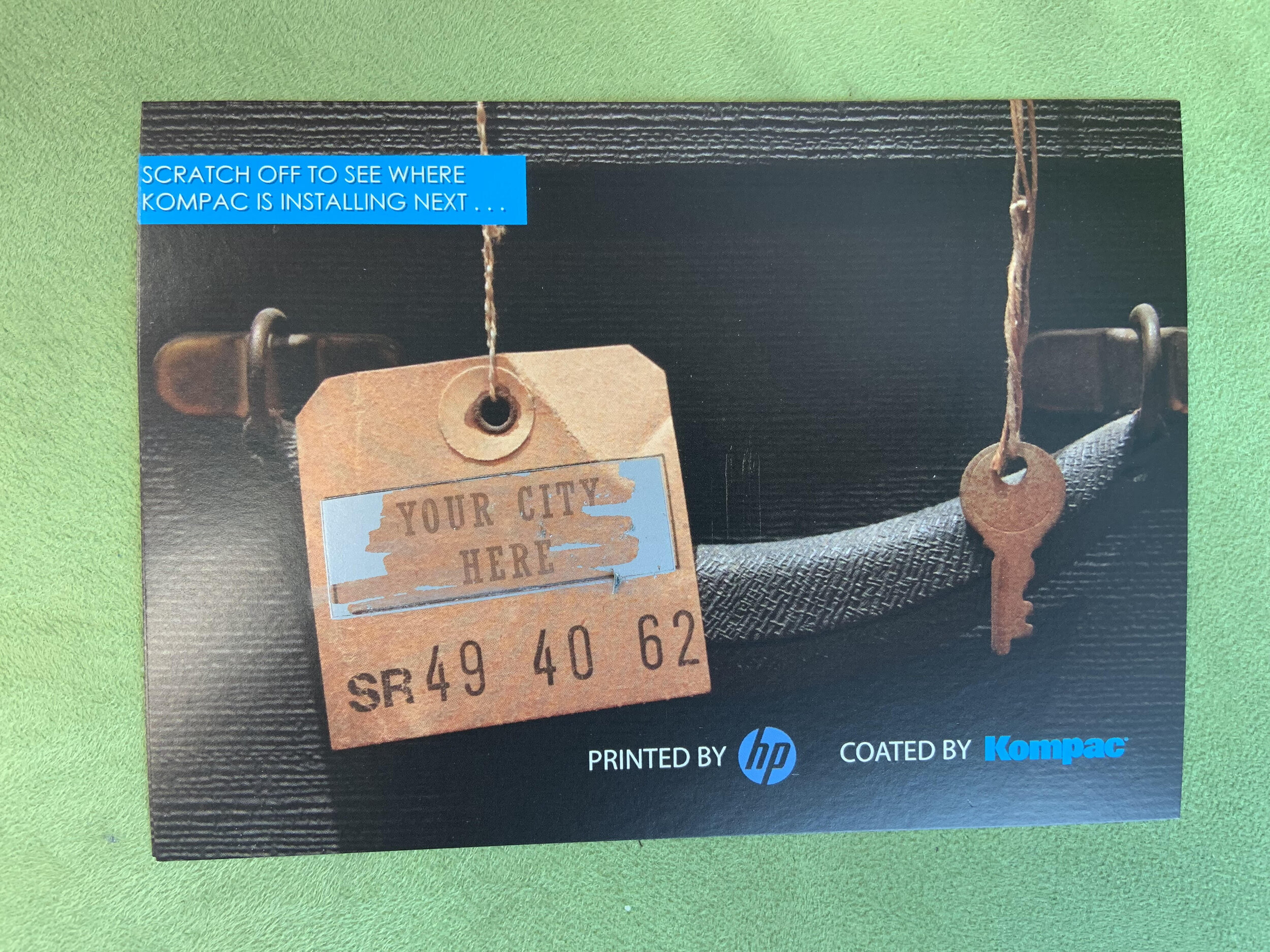

A proper coating can enhance the appearance and durability, increasing the printed product’s value. Kompac offers a wide range of coaters that can prime your already existing paper, saving you time and money. The Phoenix is just one of the several specialized Kompac coaters that can help you during this paper shortage. Available in 20” (508 mm) & 30” (762 mm), the Phoenix is a revolutionary new coating/priming system that is the most modular system available. The system can utilize one, or multiple coating and curing stations and utilizes our unique Kompac IOTech4 platform. Phoenix allows users to add outstanding finishing touches to a printed product to produce eye catching effects. Add high gloss shine, texture and grit, spot UV embellishments, scratch off spots, matte, pearlescent, soft touch feeling, spot not, areas, three-dimensional effects, and more. Capable of 250 feet (76m) per minute, the Phoenix relieves stress on low stock paper, giving power and product back to the owners.

Phoenix is great for paper handling and is designed for users looking to produce higher volumes. The Phoenix can be placed in-line with large format printers to create an automated workflow solution. Using the Kompac conveyor system, printed sheets are automatically sent to the Phoenix, where they are flood coated, cured and re-stacked. Paired with Phoenix are a sophisticated feeder and stacker allowing for full modularity of the machine. The most revolutionary aspect of the Phoenix is its integration with the IOTech4 platform which increases overall efficiency of jobs allowing quicker job turn around and can even allow users to remotely operate and monitor jobs as they go.

When it comes to providing quality solutions for our clients, Kompac goes above and beyond to meet your coating needs and deliver a product and service that you can be proud of. To learn more about the Phoenix, or if you have any questions, please contact our sales department at sales@kompactech.com