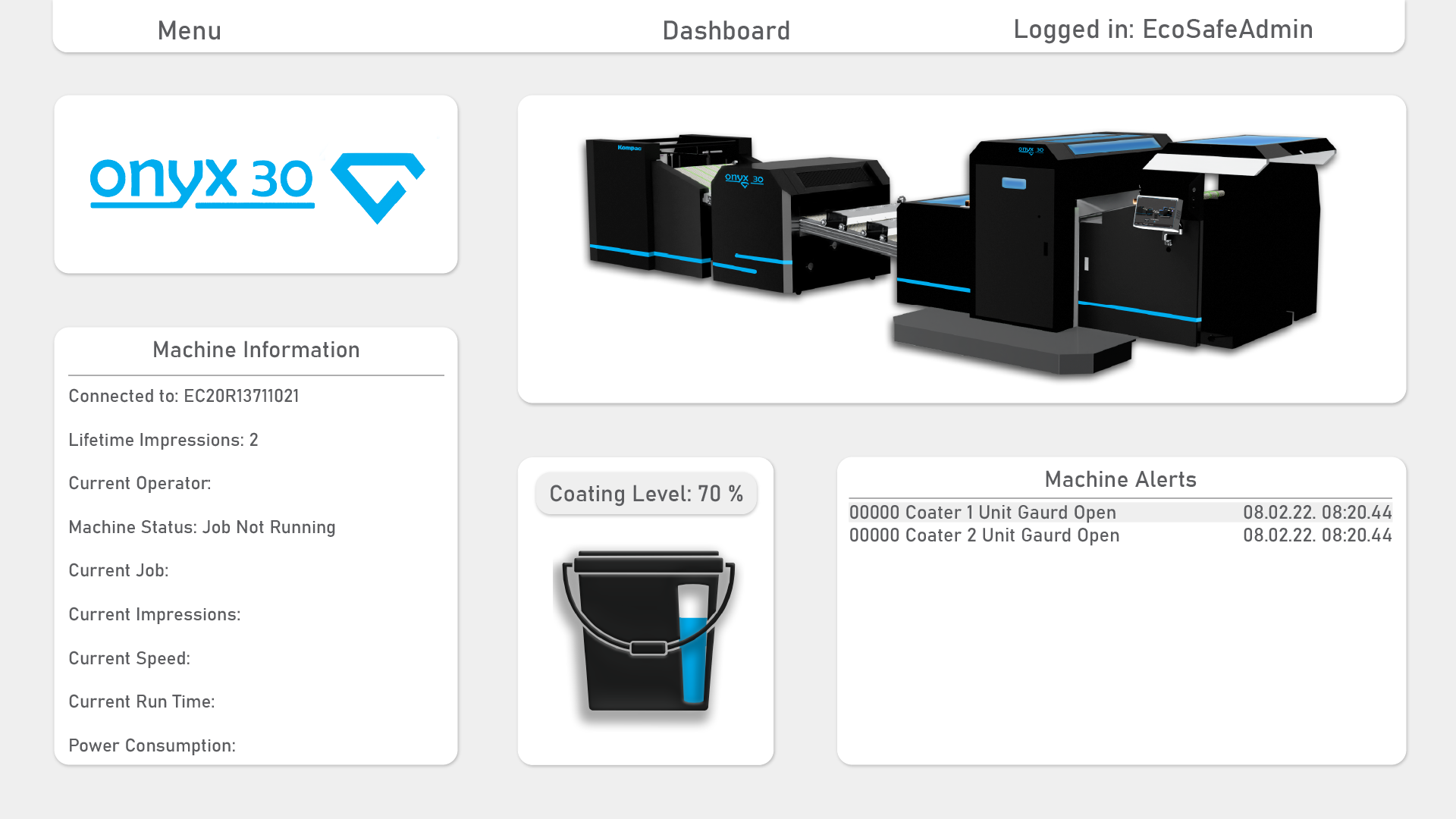

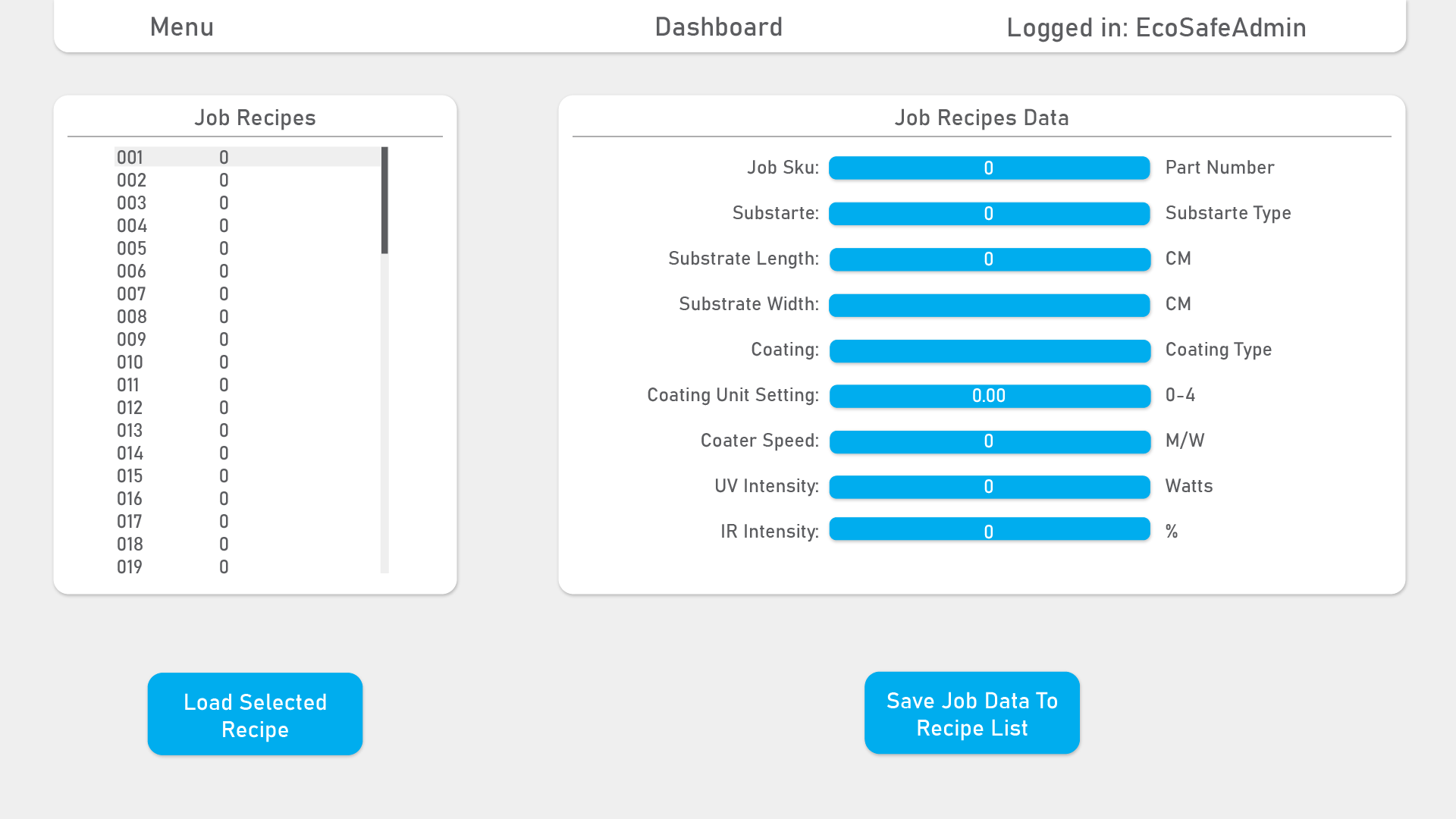

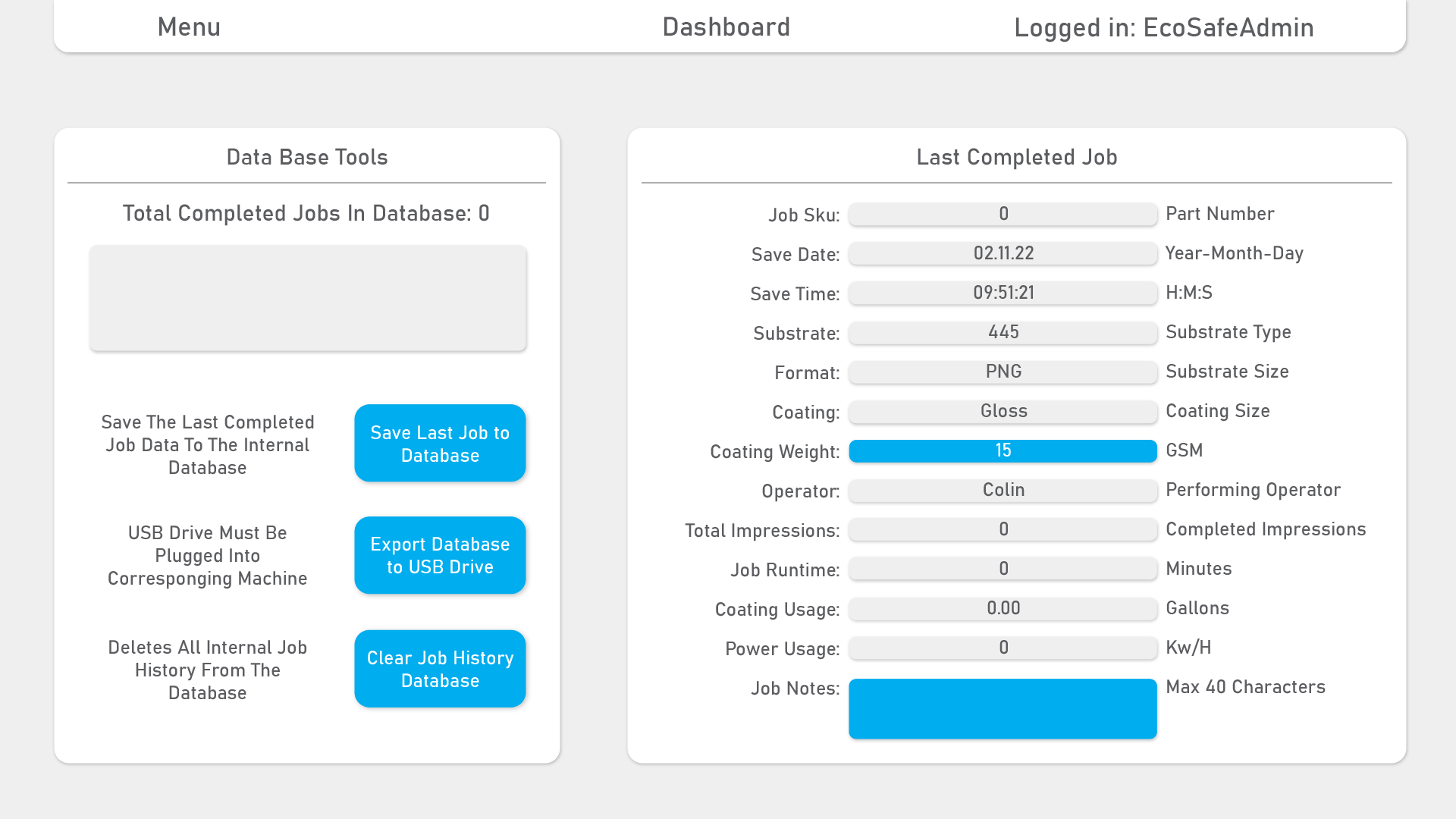

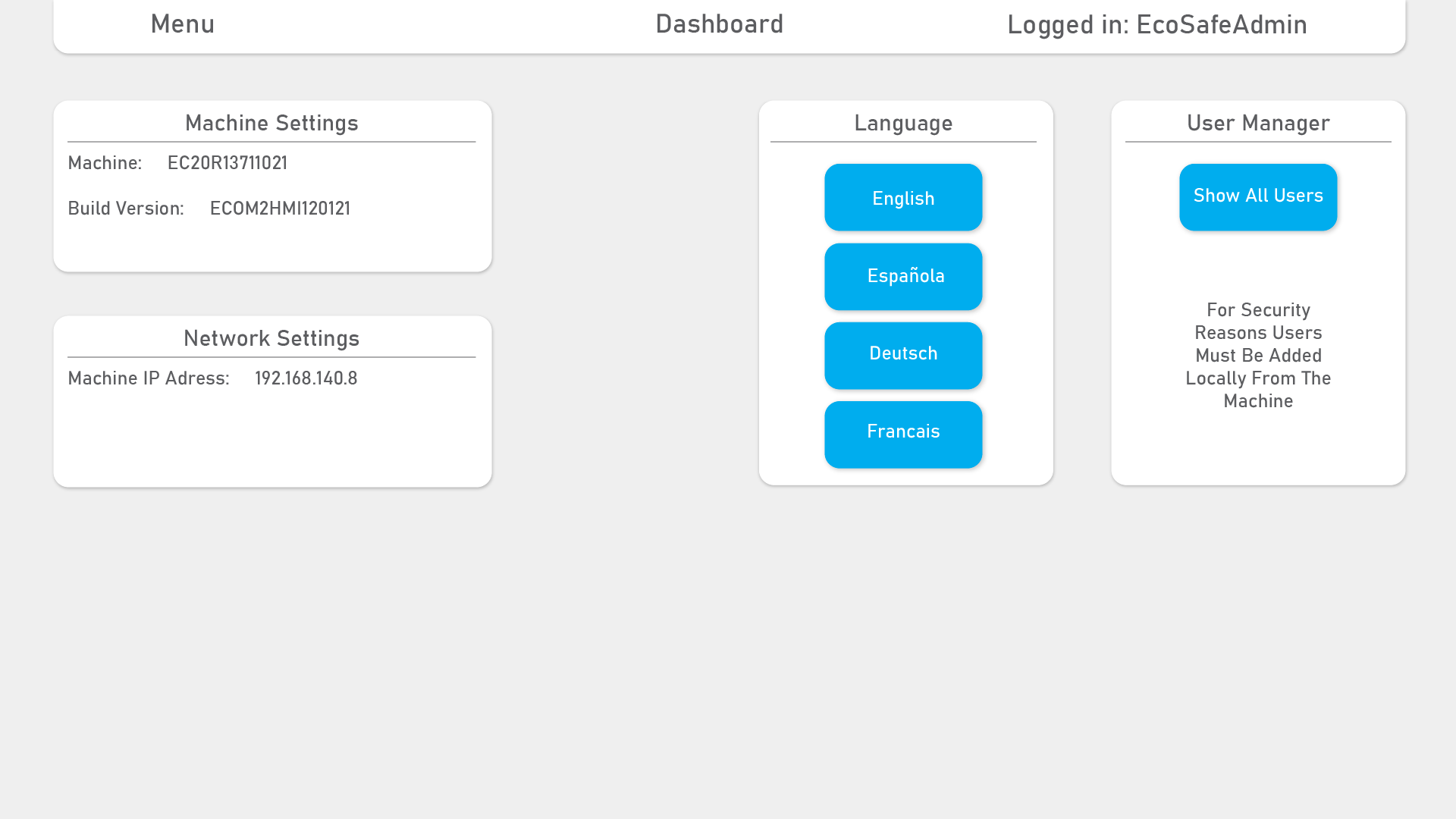

Our platform consists of state-of-the-art hardware and IOT software to provide connectivity for your operator and office staff. IOTech4 allows you to view real time statistics for information like job run time, power consumption, coating usage, and much, much more.

Maximize efficiency and minimize operator error by tracking jobs via bar code. Receive maintenance alerts and view employee performance reports, all available at the touch of your finger tips.

IOTech4 Portal & Web Interface

Wireless Tablet Control

IOTech4 Dashboard

Job History Excel Database