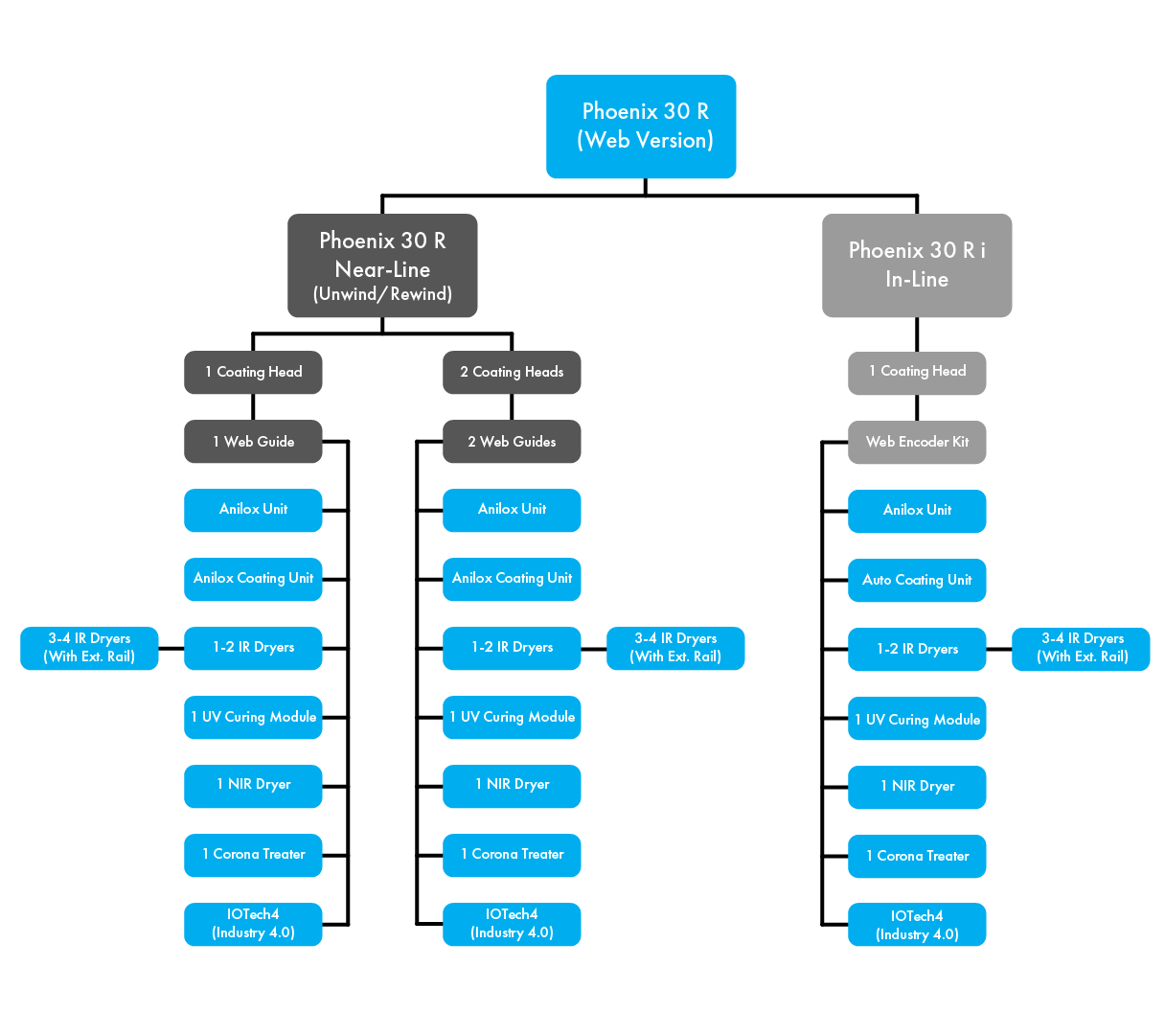

The Phoenix R is a roll-to-roll coating and priming system configured for in-line or near-line operations. The Phoenix’s revolutionary design makes it the most modular system available. This future-proof line of equipment utilizes our IOTech4 communications to add to your Industry 4.0 facility.

Phoenix R Configurations

Configurations

Auto Coating Unit: Sets the nip via servo motors; works in conjunction with IOTech4 “recipies”

Coating Sensor: Automatically detects coating level & replenishes

Corona Treating: For plastic, synthetic, and metalized substrates

High Pile Feeder & Stacker: Pallet/Dolly loadable feeder & stacker for high volumes. 2 sizes available for best sheet handling

Interface Conveyor: Allows for inline coating on select digital & offset presses

IOTech4: Communication system for better efficiency and metrics

IR/NIR Dryer: Dries aqueous coatings and assists UV coating wet-out for increased gloss

Stacker Cooling Module: Head unit contains additional fans for better drying and less bricking of the finished pile. Also contains a proofing light for better spot checking

Options

Kompac Vac: For quick & effortless 2-minute coating change & clean up

Specifications

UV & IR drying available. Can be configured pre or post coating with up to 4 IR units.

Multiple coating systems. Up to 2 coating units per system anilox or standard.

Variable length conveying pre or post curing for coating wet out or additional curing time.

High speed. Capable of 250 feet (76m) per minute.

Featuring Kompac IOTech4 network communications to increase efficiency.

Made in the USA.