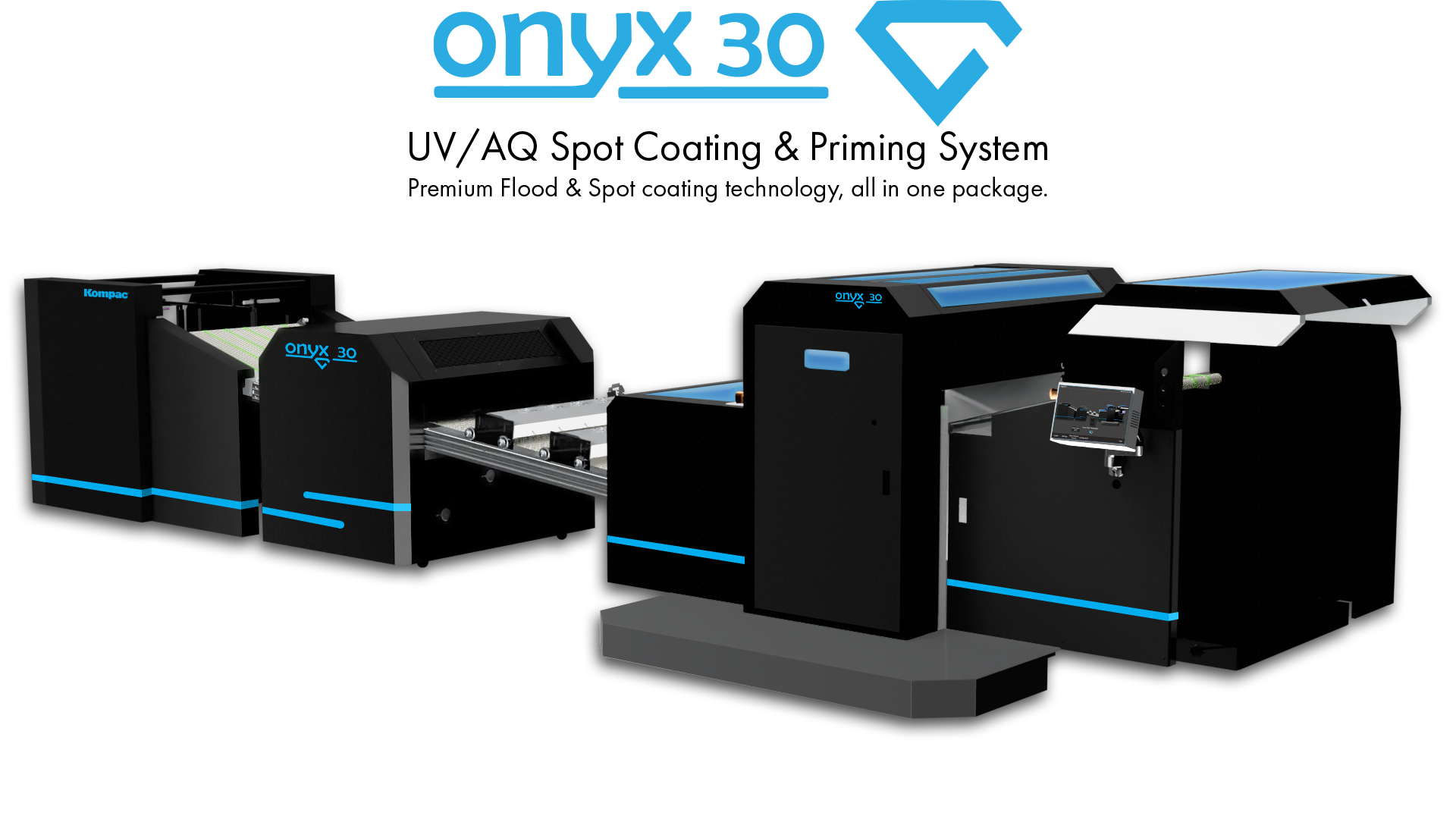

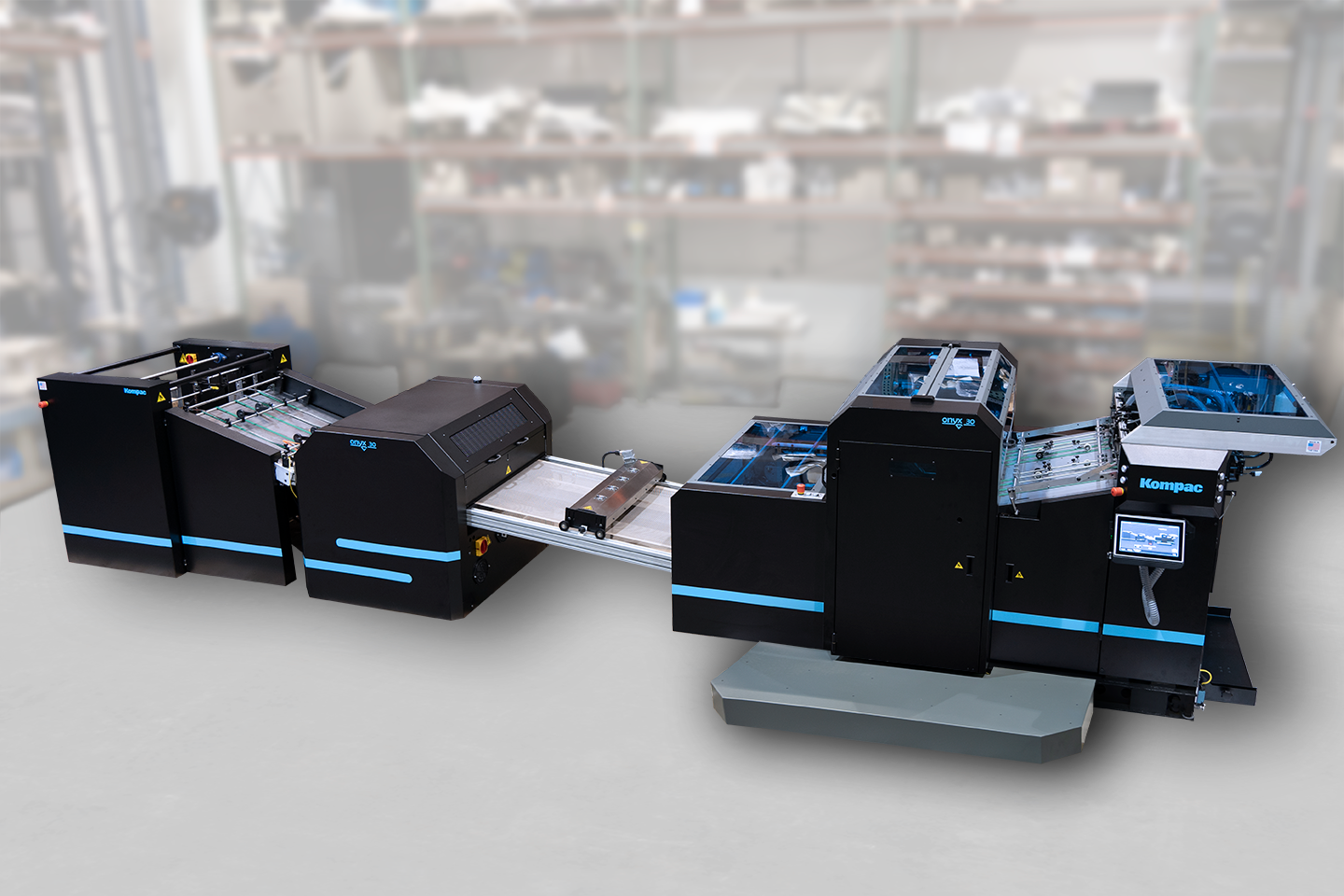

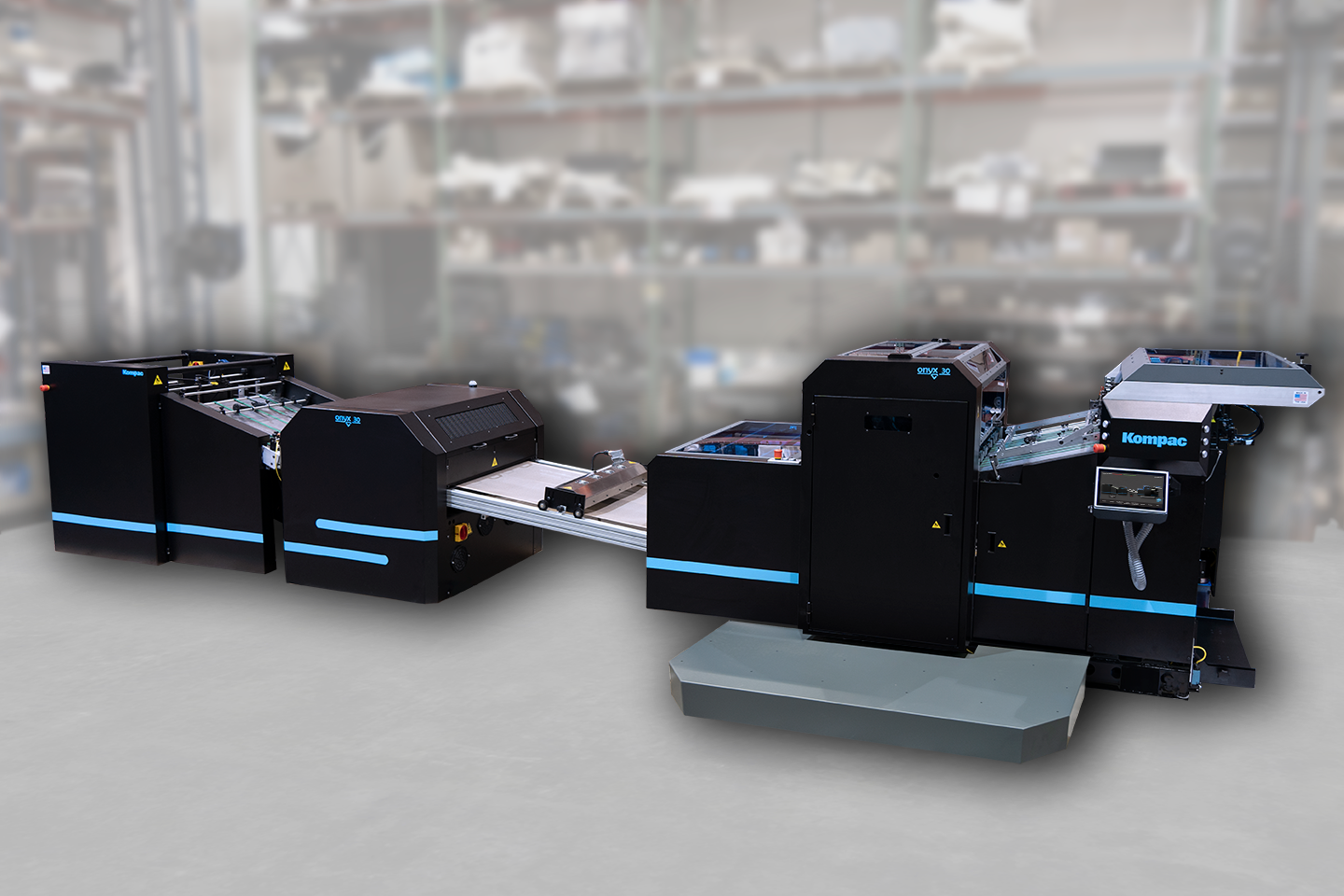

The Onyx 30 is an exciting nearline coating, priming, and die cutting system, providing a quick and easy way to apply UV, Aqueous, Primer/Sapphire, and specialty coatings to a wide variety of substrates.

From ultra thin paper to plastics, card stock and lenticular; whether digital output or offset, each job will have the visual appeal, lasting durability, protection and rub-resistant finish that your customers expect. Flood or Spot coat, the Onyx 30 is the most flexible, cost-effective coating system on the market today!

Onyx 30

Enhance your print and packaging with UV/Aqueous flood and spot coating embellishments.

Onyx 30 allows users to add outstanding finishing touches to a printed product to produce eye catching effects. Add high gloss shine, texture and grit, spot UV embellishments, scratch off spots, matte, pearlescent, soft touch feeling, spot not, areas, three-dimensional effects, and more!

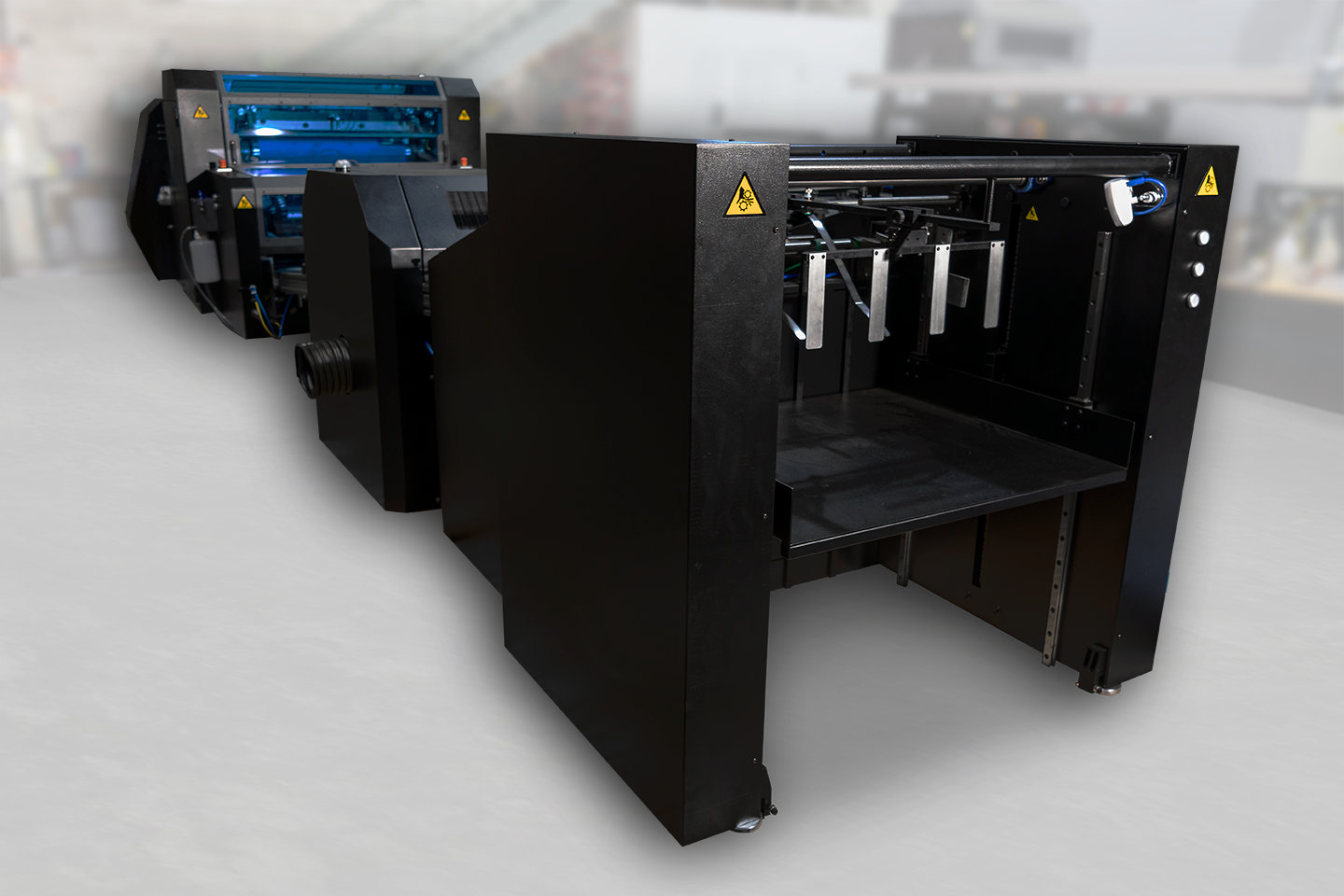

Die Cutting on the Onyx 30

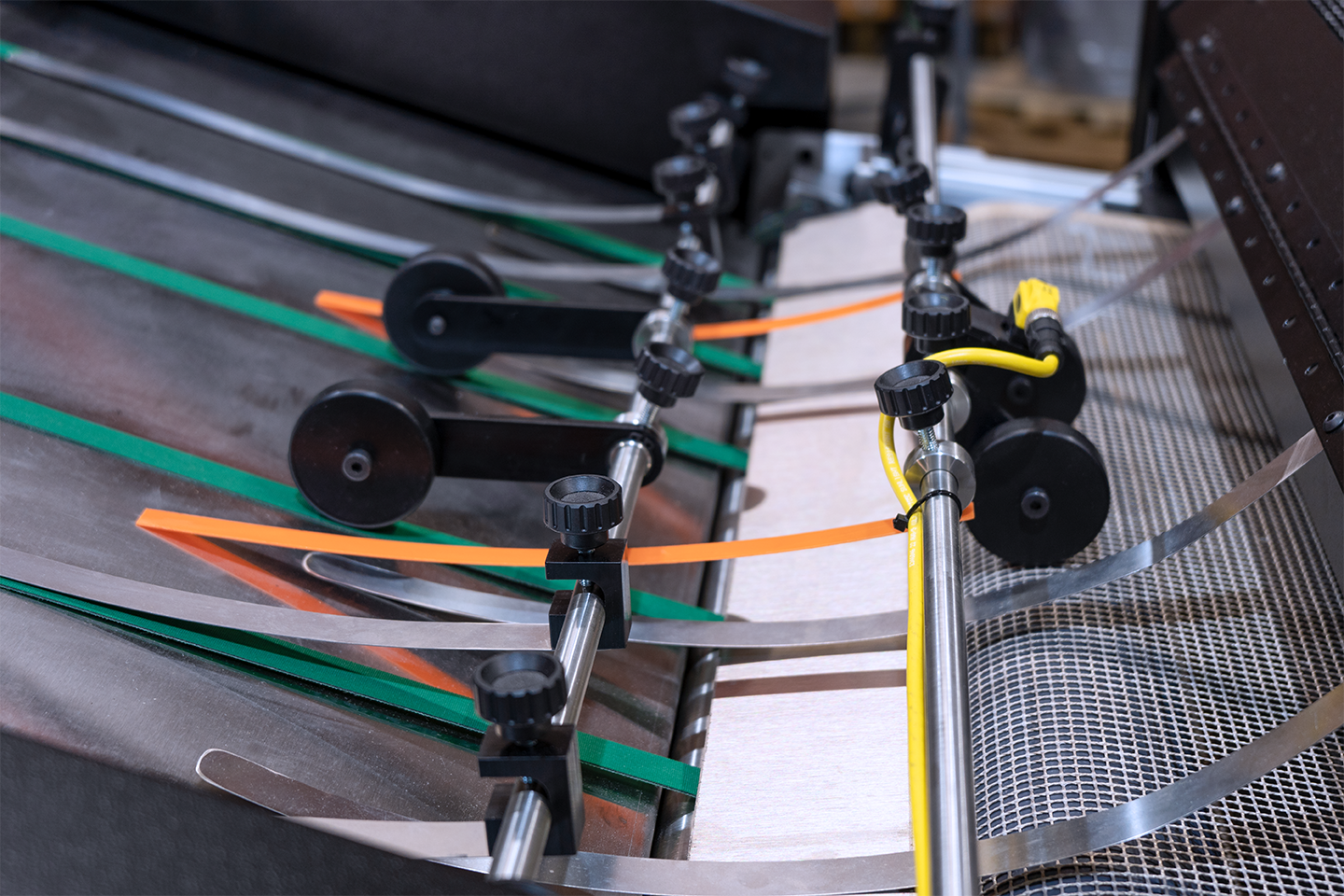

Available as optional equipment for Kompac’s UV/Aqueous ONYX 30, the semi-rotary die-cutting system provides the added ability to die-cut and perforate sheets quickly, and easily.

The magnetic die system is easy to attach, giving print service providers the flexibility to not only prime and coat printed materials – but also cut, perforate and crease sheets to produce everything from product packaging, to business cards, folders, greeting cards, direct mailers, and more!

•Soft Touch •Writeable/Glueable •Dry erase •Silver/Gold Scratch Off •Blister Packaging •Non-skid/Sand

•Food Grade Application •Playing Cards •White Opaque •More

Available Options

Optional Die-Cutting, Perfing, or Creasing.

Optional IR Dryer (or Duplex IR Dryers).

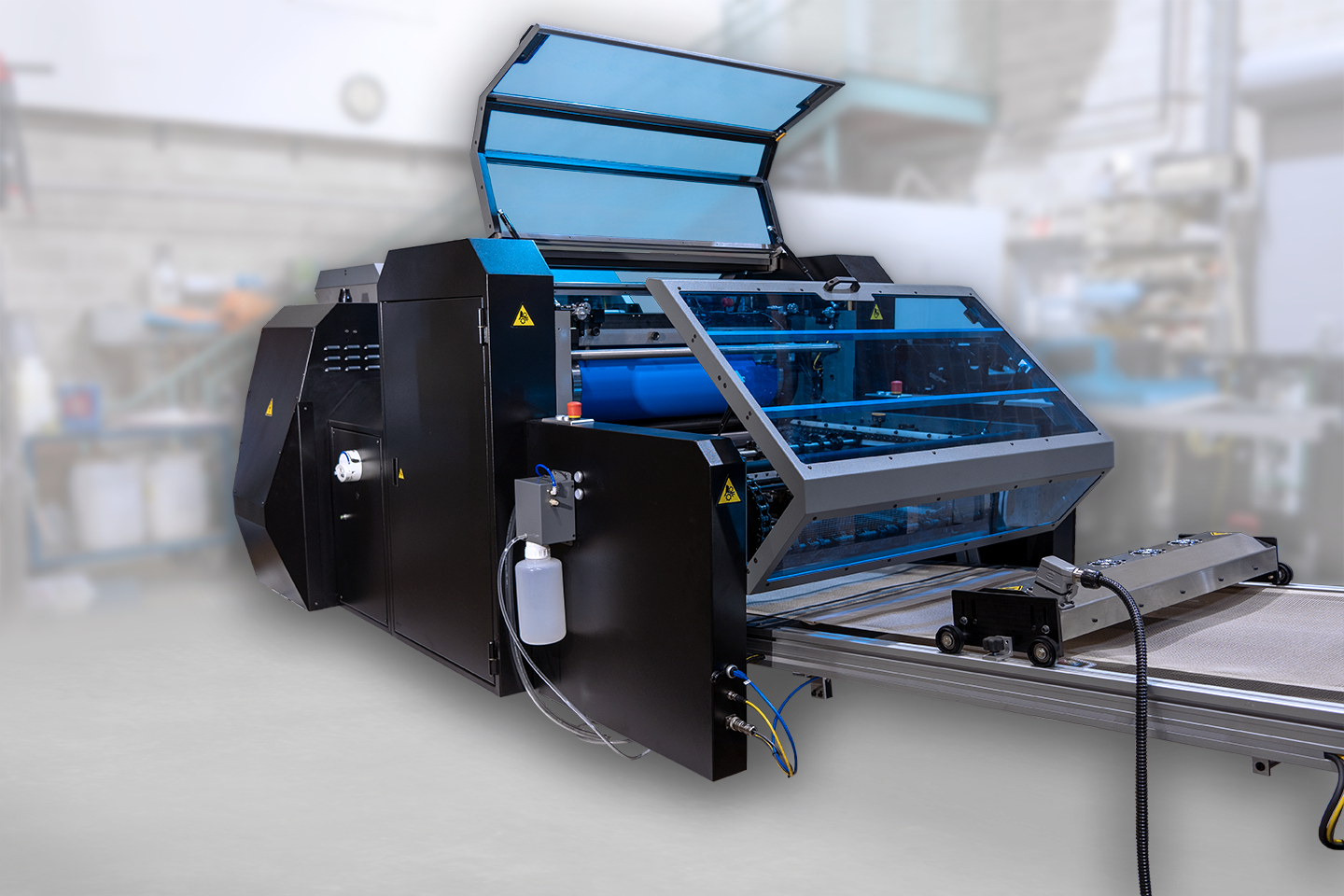

Patented Short-wave intensity bulbs with Air Curtain

Kompac Vac: For quick & effortless 2-minute coating change & clean up

Coating Sensor: Automatically detects coating level & replenishes

IR Dryer: Dries aqueous coatings and assists UV coating wet-out for increased gloss

Sheet Detection: Monitors to help prevent fires and track sheet counts

Interface Conveyor: Allows for inline coating on select digital & offset presses

Korona Treating: For plastic, synthetic, and metalized substrates IOTech4: Communication system for better efficiency and metrics

Specifications

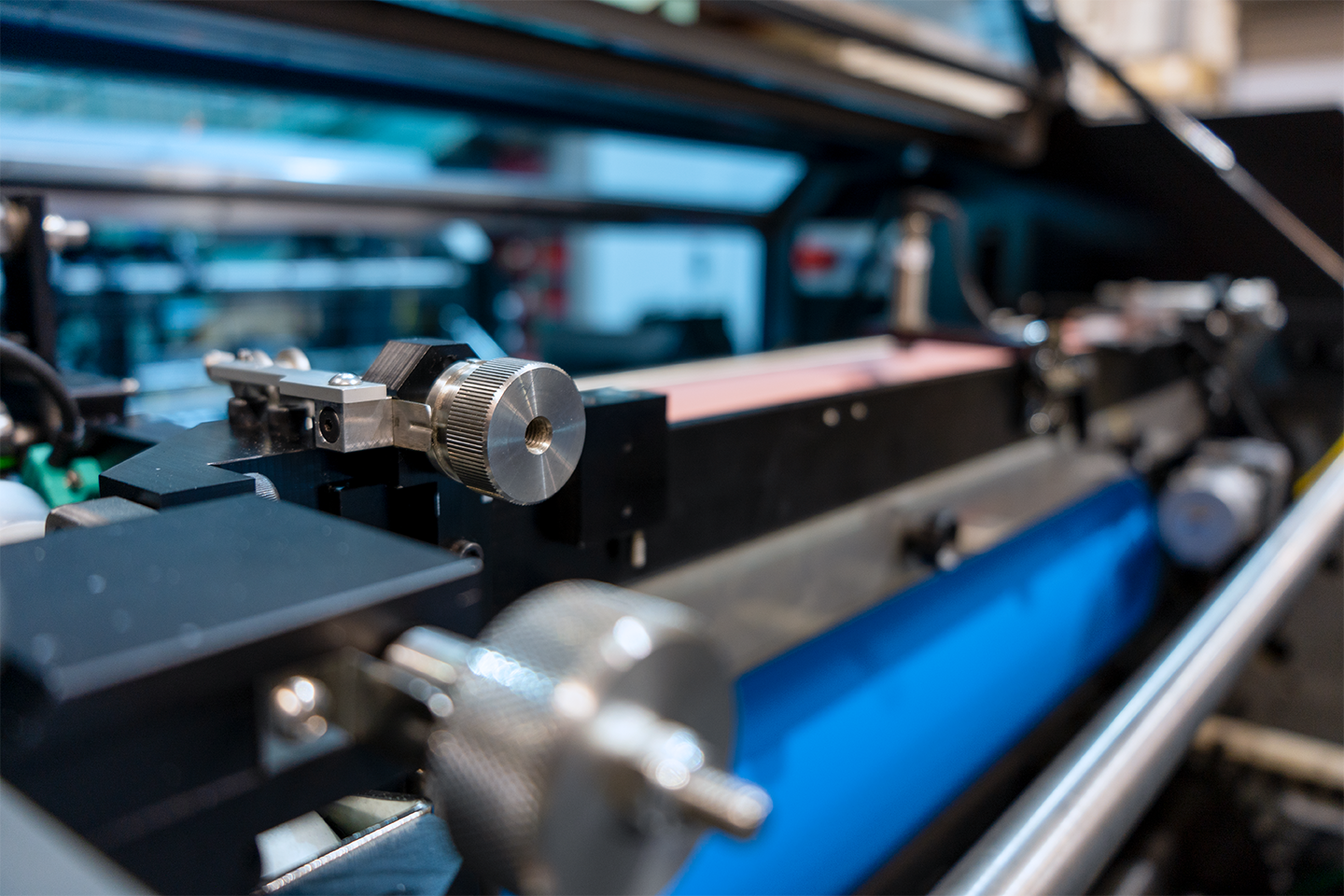

Flood & Spot Coat

Easily apply UV, Aqueous, Specialty Coatings and Primers

Optional Chambered Anilox Coating System for Soft Touch and UV Matte (in addition to standard Kompac Coating System)

Handles substrates up to 22” x 31.5” (560mm x 800mm), 22” x 30” (560 x 762mm) in Anilox Mode

Coat/Prime at up to 6000 sheets per hour

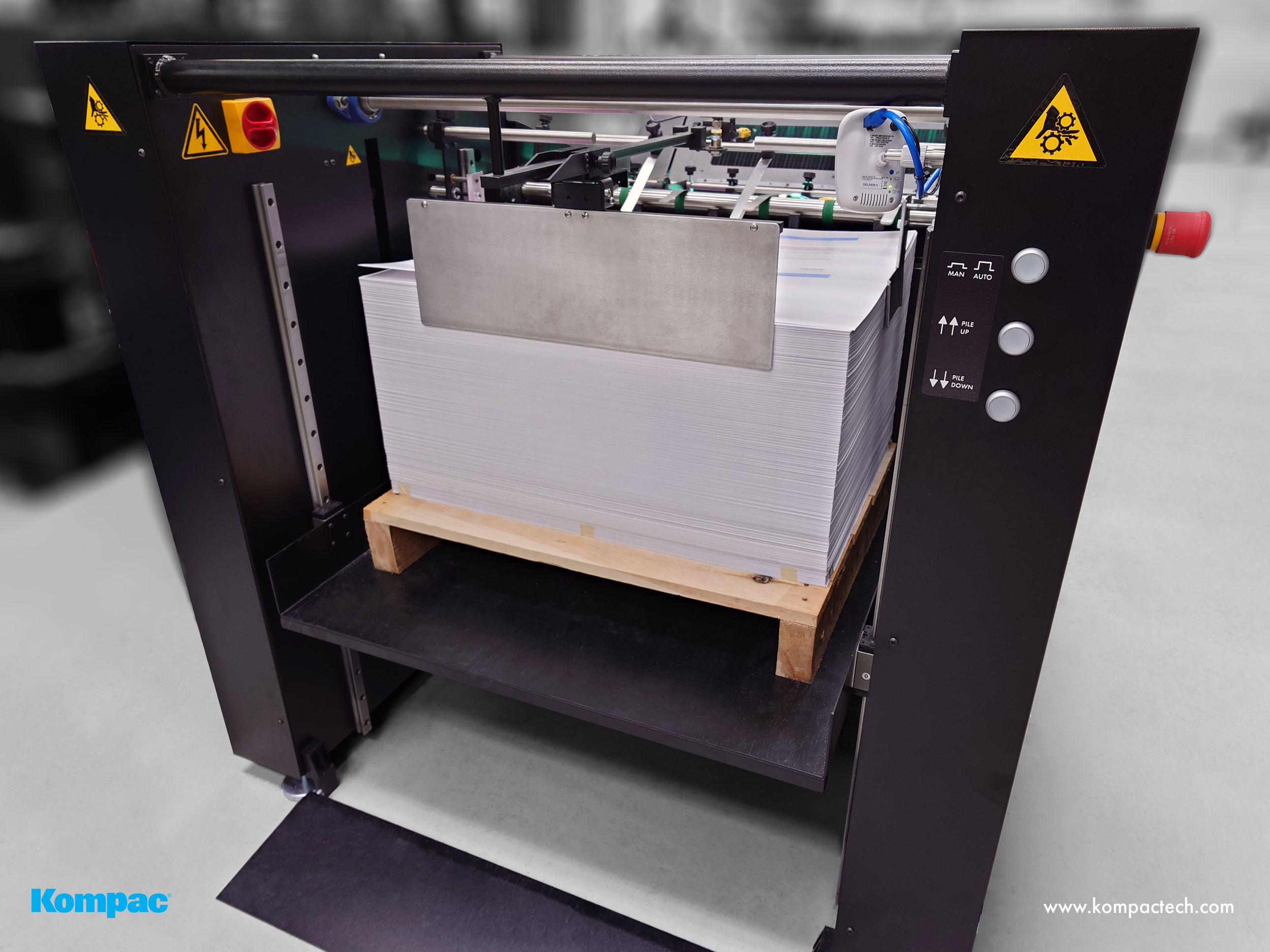

System includes the Kompac High Pile Pallet/Dolly Stacker, handles 34”(86cm) lift

Automatic Stream Feeder accepts pallets/dollies right from your digital or offset press (No “hand” loading means it is the perfect solution for variable data or sequential jobs)

Want more information?